Laser cutting

Laser cutting is a fabrication process that uses a thin, focused laser beam to cut and etch materials such as acrylic and plywood into custom designs that are created by the designer. This enables it to create intricate parts that would have needed special tools and equipment. You can also program the machine to engrave designs on the surface of the material. These methods are widely used in this module to create our parts. The machine used in SP is simlar to the one shown here.

Assignment

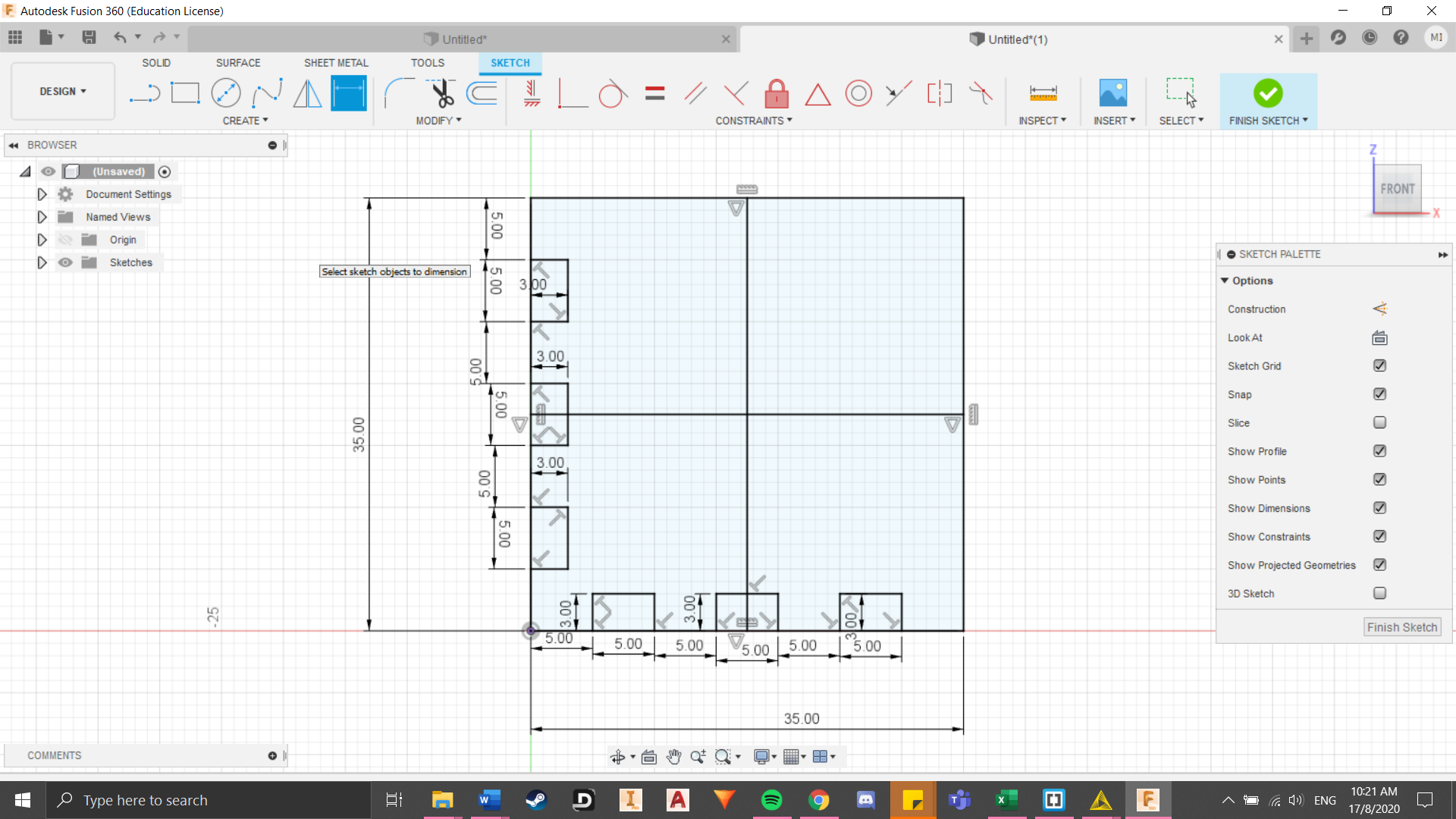

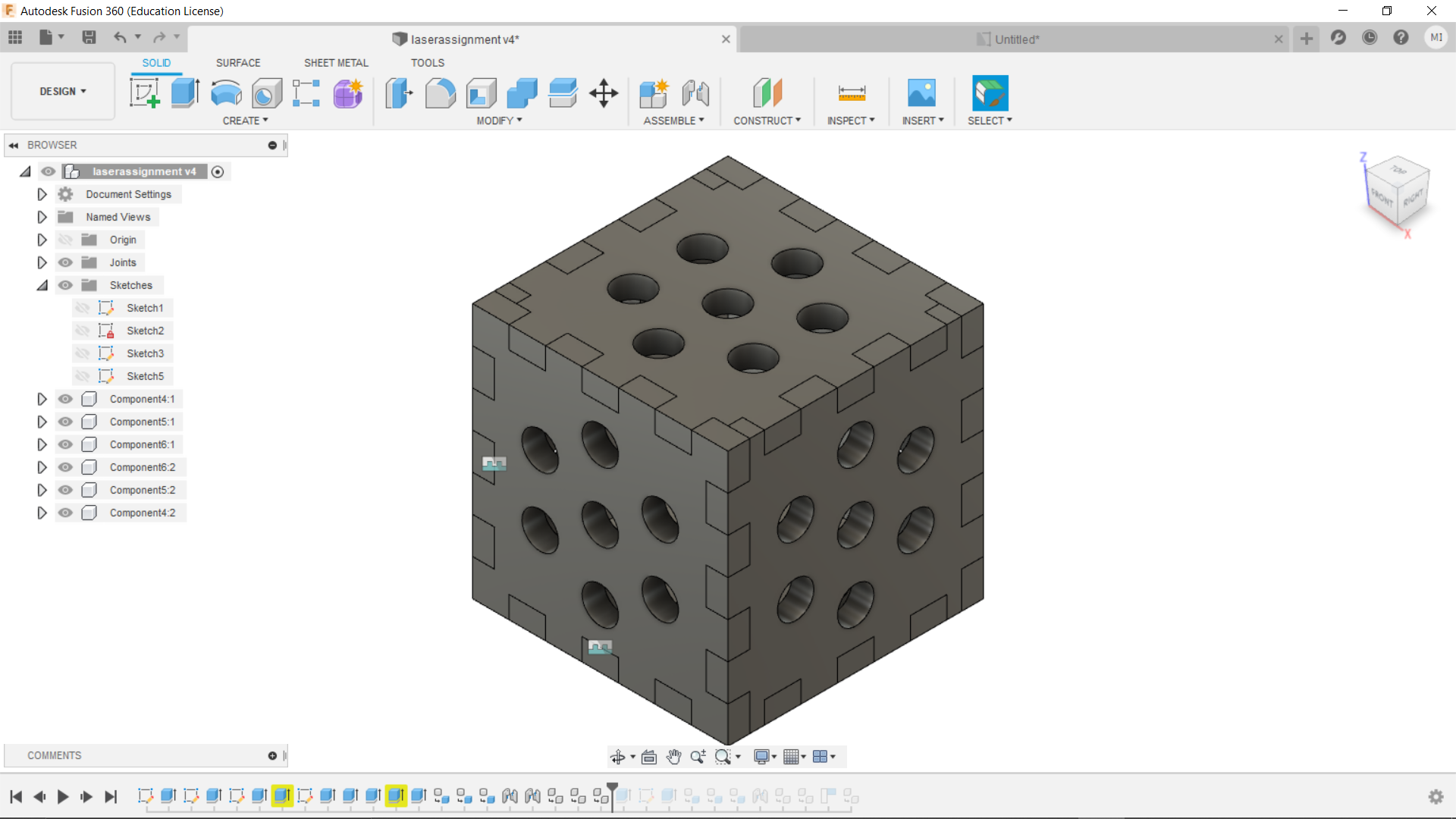

For the assignment, I created a small box, 35x35x35mm which used finger connectors. These were designed specifically to ensured that the panels would fit tightly.

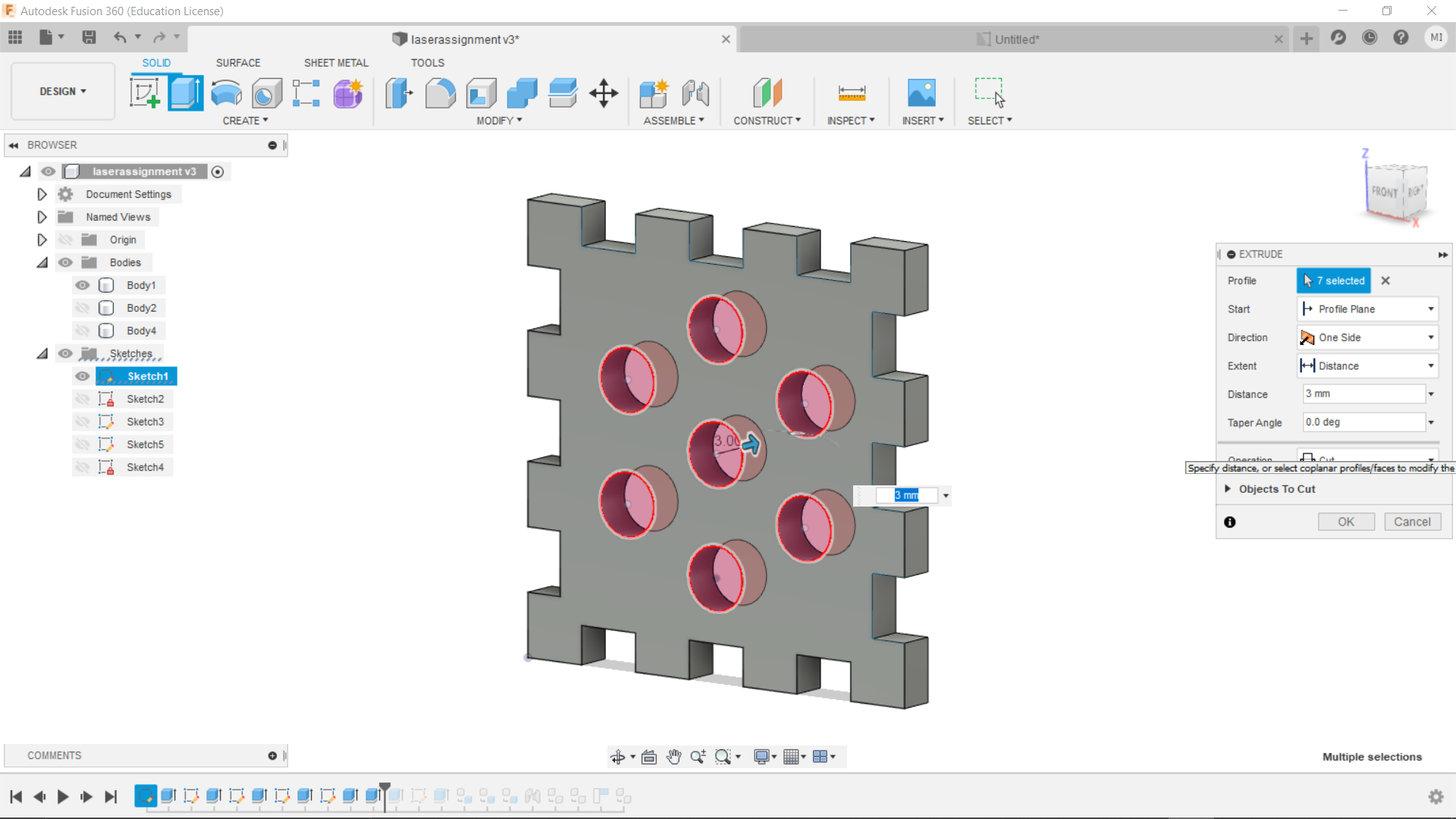

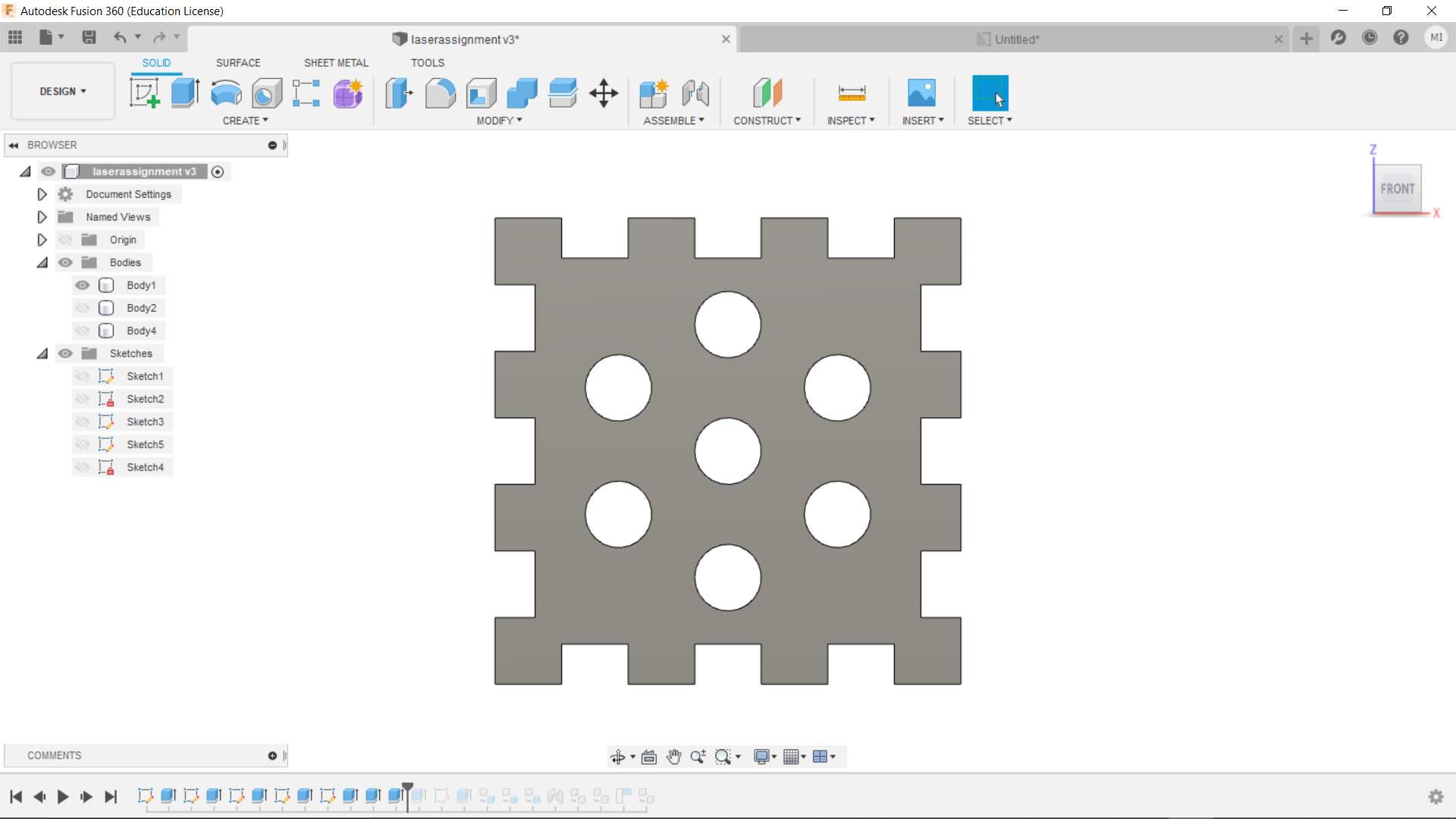

After finishing the initial sketch, I extruded the drawing by 3mm, following the thickness that was given to me by my lecturers. I then decided to draw a simple pattern onto the surface to spice things up before extruding by-3mm.

After finishing the initial sketch, I extruded the drawing by 3mm, following the thickness that was given to me by my lecturers. I then decided to draw a simple pattern onto the surface to spice things up before extruding by-3mm.

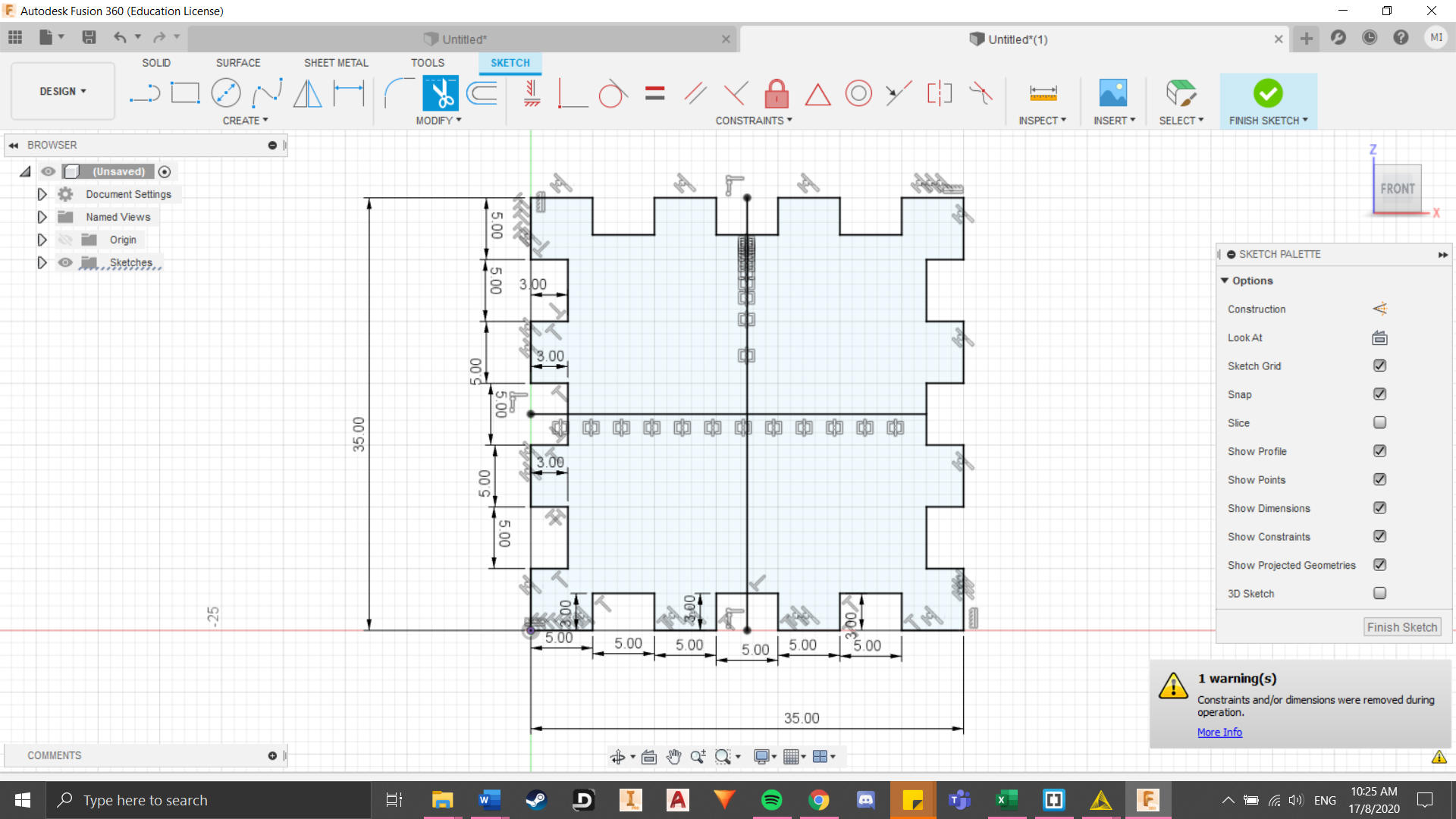

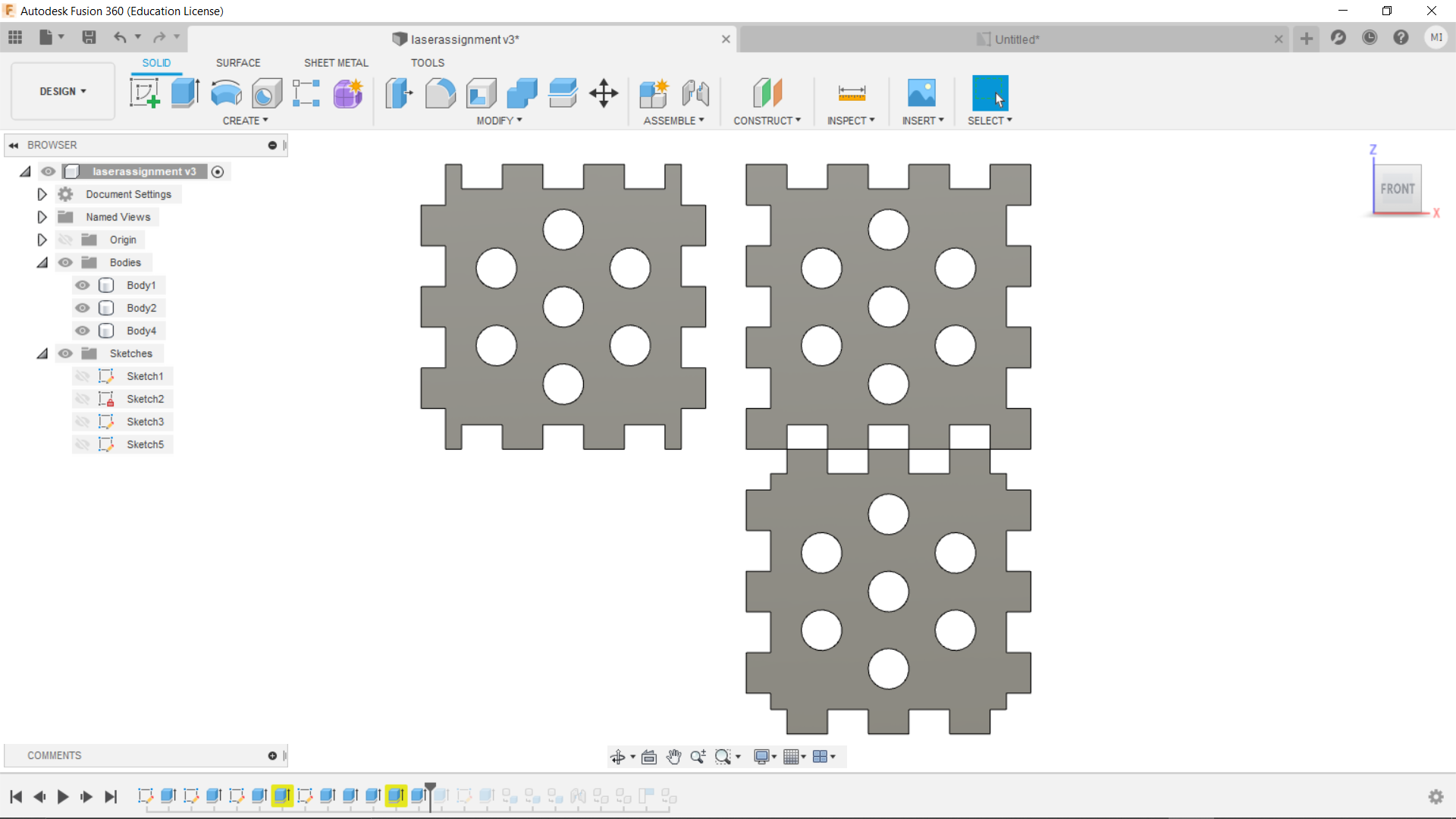

I continued doing the same process for the other sides of the box and added the 3 different sides into one file.

I continued doing the same process for the other sides of the box and added the 3 different sides into one file.

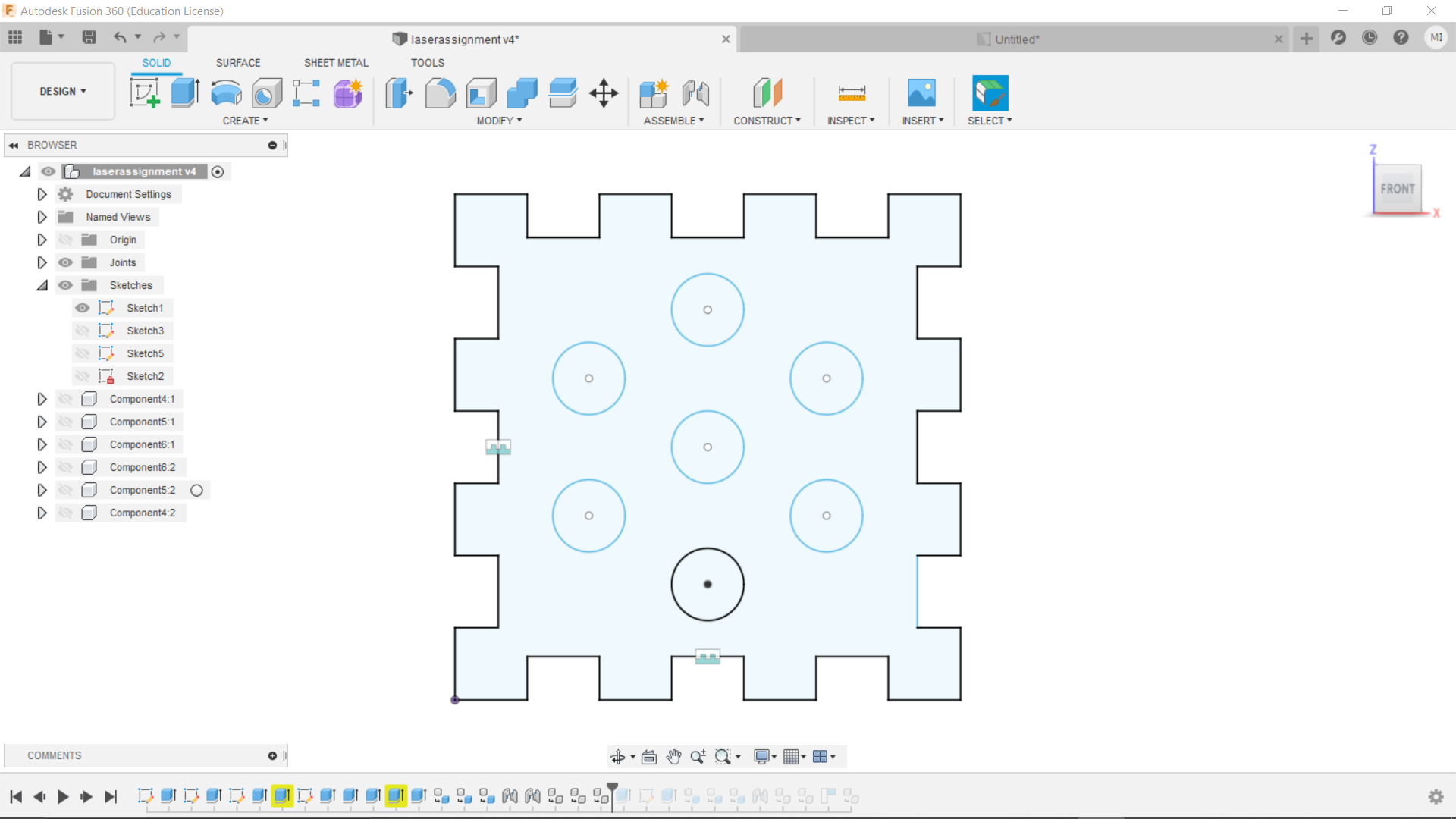

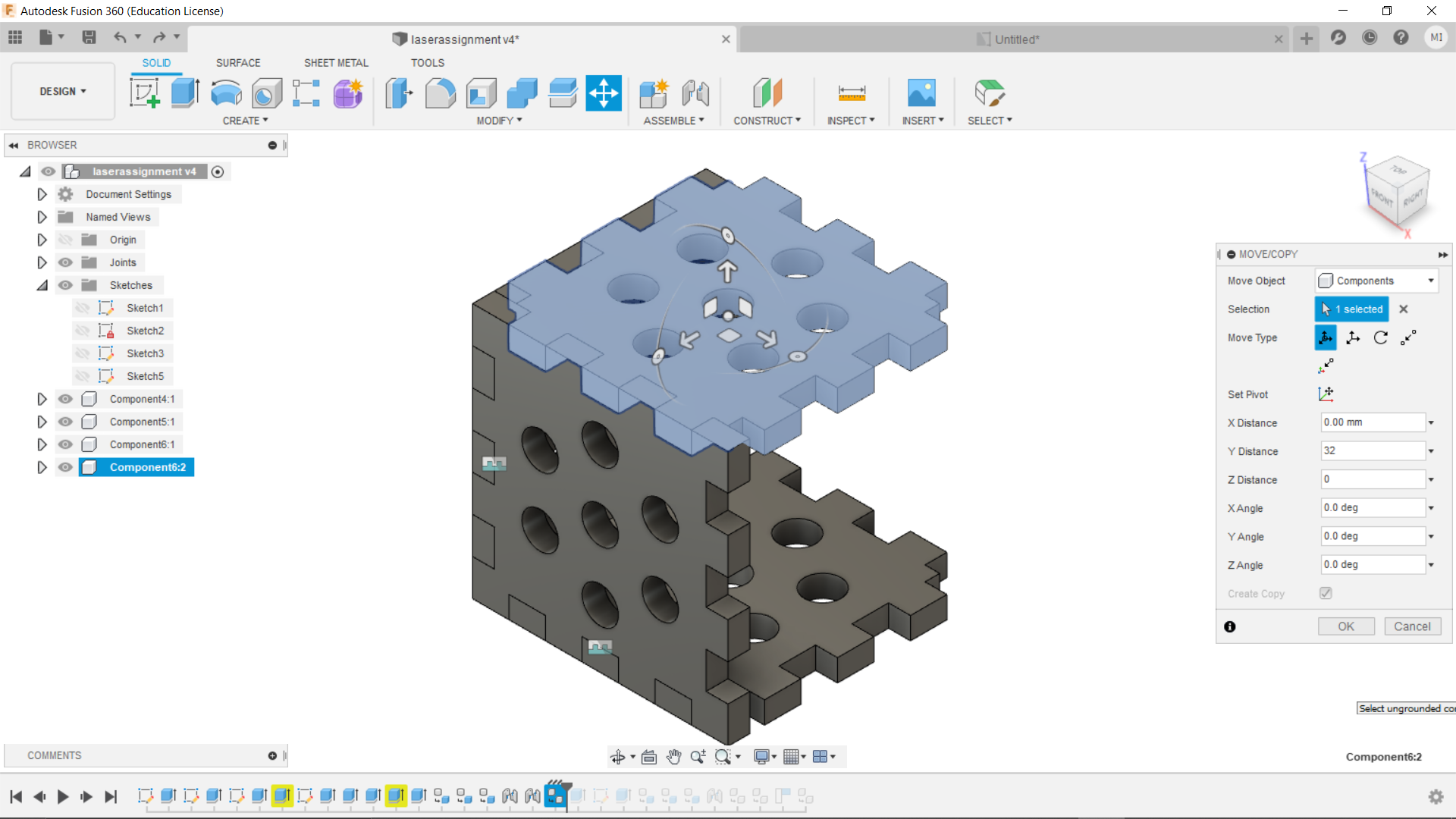

It took me awhile to figure out how to join the parts together. But first I had to duplicate the parts by simply by using the copy and paste functions. Then I used the move function to move the panels into place.

It took me awhile to figure out how to join the parts together. But first I had to duplicate the parts by simply by using the copy and paste functions. Then I used the move function to move the panels into place.

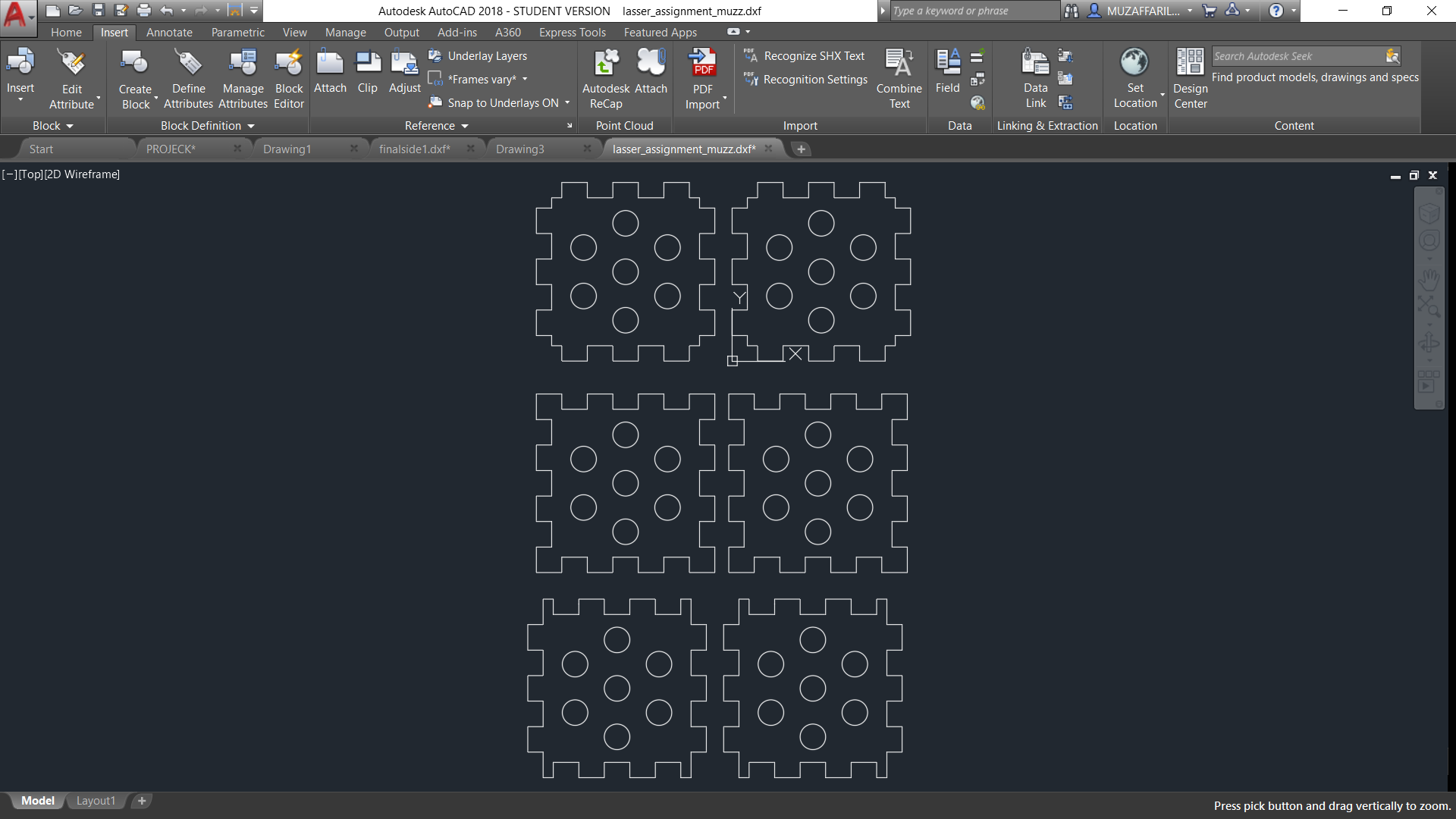

Im quite happy with how the final product turned out. Now all thats left is to transfer the individual parts to autocad to be laser cut.

Im quite happy with how the final product turned out. Now all thats left is to transfer the individual parts to autocad to be laser cut.

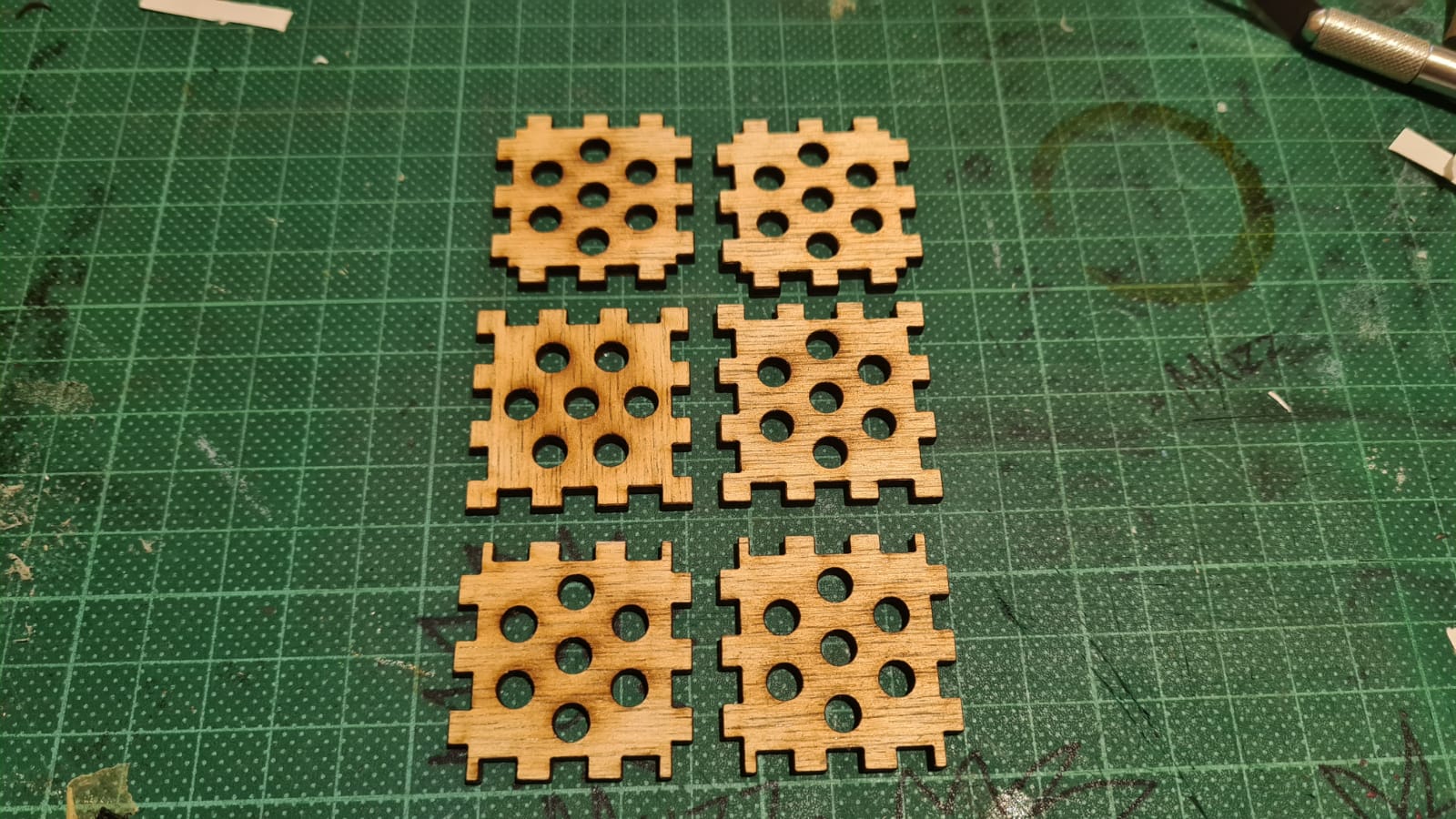

Here are the parts after the cut. It was fairly easy to put together. Thanks to the tolerance I gave in my drawing, the box was able to be put together by press fit without any glue.

Here are the parts after the cut. It was fairly easy to put together. Thanks to the tolerance I gave in my drawing, the box was able to be put together by press fit without any glue.